- (914)916-0505

- [email protected]

- 60 Morrow ave, Scarsdale NY,10583

- (914)916-0505

- [email protected]

Technology

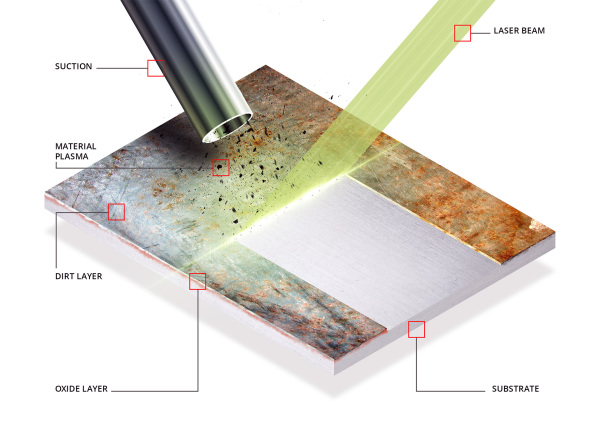

HOW DOES LASER CLEANING WORK?

LASER CLEANING EXPLAINED IN 7 STEPS

- The laser shoots bullets of infrared light to the surface

- The contamination absorbs the light’s energy

- The contamination heats up very quickly

- The substrate remains cool

- The difference in temperatures causes the contamination to ‘shrink off’ the surface

- The dirt can be vacuumed off

- Result: a clean surface that has not been damaged!

HOW LASER CLEANING WORKS

Industrial laser cleaning – or ablation – is the process of clearing away undesired material from a solid surface by irradiating it with a laser beam. By absorbing the energy of the laser beam, the targeted material is heated very quickly, making it evaporate or sublimate. As the surface below does not absorb any energy, it stays untouched.

By manipulating the laser flux, its wavelength and its pulse length, the amount of material that is being removed by a single laser pulse can be controlled with extreme precision. Making laser cleaning equally suitable for rapid and deep rust removal as for removing only one thin layer of paint, without damaging the base coat.

ADVANTAGES OF LASER CLEANING

As laser cleaning does not use any chemical solvents or other kind of consumables, it is environmentally friendly and safe to operate.

Other advantages:

- dry and clean

- highly accurate

- noiseless

- non-contact technology

- easy to use

- easy to automate

- safe for any kind of substrate, even very delicate surfaces

- unrivaled level of control

- no unwanted side effects

- not abrasive or potentially hazardous

- suitable for hard-to-reach areas or surfaces

- suitable for use in hazardous or dangerous environments

- lower operational costs than most other cleaning techniques

- absolute minimum of residue, mostly dust

- minimal maintenance

- quick installation and setup time

INTERESTED IN LASER CLEANING?

Interested in what laser cleaning can do for you? Dres Laser Rustgone performs tests on a daily basis. Book a demo or test to see what laser technology can mean for your company.

Get in Touch

CONTACT US TODAY

We are here to help, so contact us today to discuss your laser cleaning needs and see what our trained professionals can do for your business.

-

Call Us:

(914)916-0505 -

Email Us:

[email protected] -

Address:

60 Morrow ave, Scarsdale NY,10583